ANTECEDENTS—RUBBER AND THE BIRTH OF PLASTICS MACHINE TECHNOLOGY

I got my first writing assignment when I was in fifth grade. I was to use some prearranged sources and put together a report on Charles Goodyear. I remember it because it was so heroic a story—Goodyear, the lone inventor, patiently experimenting with various chemicals in his life-quest to develop a stable compound out of a black goo that was soft in the summer and hard in the winter, sacrificing first his income, then his family’s resources, and eventually his health before finally producing what we know today as rubber. The lesson was obvious even to a fifth grader: success demands sacrifice.¹ Focused, as it was, on Goodyear, I remember thinking that I still knew nothing about his workshop—what did he have in it? As it turns out, the concurrent, and requisite, development of the processing machinery needed to make rubber products was as tortured a path as that trod by Goodyear.

The first utilization of what we call rubber dates back over three millennia. Mesoamerican natives developed a trade in its precursor form in Brazil, spreading to Central America and across the Caribbean Sea. When Christopher Columbus returned to Hispaniola in 1495 he observed natives playing with rubber balls of amazing elasticity, bringing back to Europe samples of this unknown material. Primitive rubber is a mix of the sap of the

Castilla elastica and the morning glory vine,

Ipomoea alba mixed in various ratios. With such materials the natives made balls, headdresses, the soles of sandals, and binders for arrow points. The sap, a form of latex and consisting mainly of isoprene, was sticky and gummy, but when comingled with the sap of the vine and boiled or smoked over a fire, it cross-linked, became harder, and lost most of its adhesive properties.² Isoprene comes in two versions,

cis and

trans—gutta percha serving as an example of the more flexible

trans variant. Latex is surprisingly common—milkweed and dandelion both ooze it when their stems are broken—but meaningful collection requires a high-volume source, something that only the

caoutchouc tree, “the tree that weeps,” of South and Central America offered. In Europe it remained a curiosity for over two hundred years. In 1725 Charles-Marie de La Condamine studied its origins and properties, then published his results. But the hot trip back to Europe fermented his samples, leaving him with nothing more than a stinky goo and killing off any further interest in the product.³ Another century would pass before anyone would find useful applications beyond those already underway in Central America.

That opportunity came in 1818 when Charles Macintosh ran across a paper written by J. Syme, Esq., detailing his efforts to dissolve caoutchouc in naphtha, which he undertook so that he could develop a fluid that would be “free from the objections to which the known solvents of that remarkable substance [turpentine] are all more or less liable.”⁵ After reading Syme’s paper Macintosh started thinking that he might then apply the liquefied rubber to a wool fabric, so he painted one side of a sample of wool fabric with his rubber solution, then applied another layer of wool, adhering the two. Although smelly, the resulting fabric was rendered waterproof. Macintosh instantly recognized its value—he had already made a fortune working with fabrics, mainly making alum mordant for dying wool, and knew how desirable waterproof clothing would be in Scotland’s dreary climate. In 1823 he patented (No. 4804) his “Macintosh” fabric and two years later joined with Thomas Hancock in his works in Manchester.

The industry required that the rubber be shred, then mixed and liquified to assume a form that would be suitable for calendaring. Hancock accordingly developed his “pickle,” a shredder that tore the chunks of caoutchouc into parts small enough to be liquified in a solvent. His pickle, along with his “spreader,” enabled him to produce rainwear of various kinds, the ubiquitous “mackintosh” then entering the vernacular for raincoat. But the fabric remained problematic—it was still too soft and smelly in the summer and stiff in the winter.

In the United States making something useful out of caoutchouc was equally alluring, and the problems equally challenging. Sometime prior to 1834 Edwin Chaffee, John Haskins, and Luke Baldwin formed a company to make just such items. They sold their original company, which soon led to the formation of Roxbury India Rubber Company. The new company manufactured a number of goods, including life preservers and carriage tops. But their products suffered the same fate as the Macintosh coats—stiff in the winter and gooey in the summer. In the late summer of 1834, Charles Goodyear stopped by the New York storefront of the Roxbury India Rubber Company, inquiring whether the firm could use an improved valve for the life preserver that he had seen several months before. Goodyear’s hardware business had failed, leaving him penniless, and he was looking for another means of income. But the proprietor regretfully revealed that the Roxbury firm was probably going bankrupt—many of the articles sold during the past two years were being returned. Once the summer warmth had heated them sufficiently they melted into a sticky, stinking mass. Goodyear, sensing an opportunity, turned his attention to the stabilization of rubber, spending his family’s meagre assets on rubber and various additives. But because of his embarrassed financial condition he often found himself conducting his experiments within the confines of debtor’s prison.

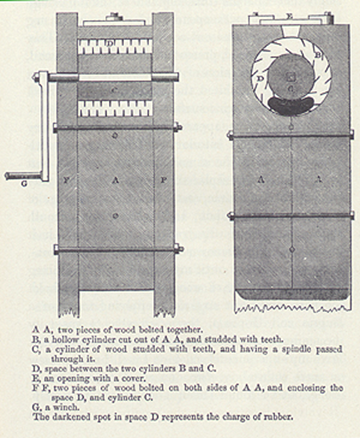

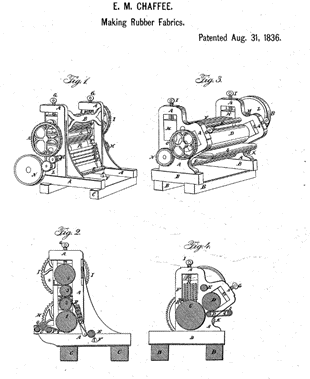

Similarly, when the rubberized carriage top of Nathaniel Hayward’s buggy stuck together that summer he decided to find out why. He sold his livery business in Boston in 1834 and rented an abandoned mill in Easton, where he experimented with rubber for the next two years, with uneven results. He started making waterproof white aprons using white lead, magnesia, and whiting as additives. They were still not white enough, so he struck upon the idea of using sulfur to further whiten the surface. Hayward then noticed that once treated with fumes of sulfur the fabric lost its persistent adhesion, giving him his “first intimation of the power of sulphur to prevent rubber from becoming soft and adherent when warmed.”⁷ He began making cloth for the Eagle India Rubber company, whose main inventor, Edwin Chaffee, had developed a two-roll mill that dispersed the additives into the rubber then calendared the mixture onto a fabric with heated rollers.⁸ Unfortunately for Chaffee and Hayword, a financial panic in 1837 ruined that company too, throwing Hayward onto his own resources. His fabrics were indeed an improvement, and he won awards for them, but orders were scarce.

By August 1838 Goodyear had recovered, somewhat, and he sent an order to Hayward for thirty yards of rubber cloth, which Hayward produced. It was treated with sulfur, and, according to Hayward, it was from that cloth that Goodyear “got the scent of brimstone.” Now onto the chemical composition of an improved form of rubber, Goodyear inquired as to its patent potential. He found that Hayward was indeed making such an application, but when the patent office returned it, Goodyear offered to put the patent in his name and buy out Hayward, then employ him in the factory for roughly one year.

That patent was issued in Goodyear’s name in November 1838.⁹ Now thinking that his trials were nearly over, Goodyear manufactured and sold mailbags and life preservers, only to discover that they too failed in a short time, despite the addition of sulfur. Once again he faced financial ruin. But in January 1839, while in a discussion with friends, he gesticulated a bit too excitedly and accidentally exposed a sample of sulfonated gum to a hot stove. To his amazement, it did not melt—it charred a bit but remained pliable. He realized that he had discovered how to stabilize rubber. However, as is always the case with commercialization, he did not have a stable process—only an idea of one. How much sulfur, how much heat, for how long? Over the next three years he experimented with the variables in his factory, residence in which he alternated with stays in his familiar “hotel room” in debtor’s prison. It must have seemed like he would never get out: by 1843 he had amassed $49,566 in debt and again declared bankruptcy. But he was making progress, and by June 1844 with help from family members he managed to patent his process.¹⁰

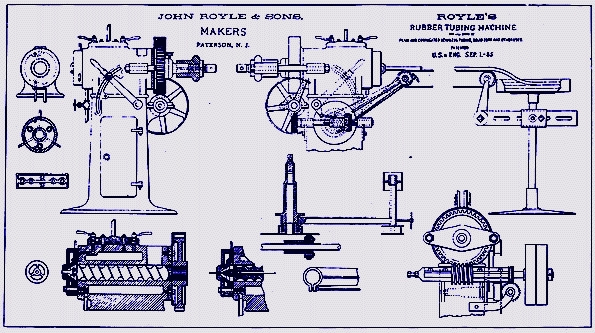

Goodyear is certainly the best known, and the first to patent, the stabilization of rubber, which led to its subsequent commercialization. But it requires far more than the knowledge of the material process to make products, and here the story gets more complicated. The first rubber extrusion screw was patented by the Kerite Company in 1865 and was powered by a water wheel and heated with a steam jacket. It coated wire with gutta percha. Other patents were issued to Mathew Grey and Francis Shaw in the UK and John Royce in the US.[1] Twenty years later John Royle and Sons patented the first extrusion machine for rubber tubes.[2] As we observe frequently in the history of technology, rapid expansion of technology occurs when a disruptive technology branches into a new field. In the case of the rubber industry, however, it seems that the disruptive technology made a new territory—first the bicycle tire, then those for automobiles, then other tubes, hoses, and gaskets.

One reason why the plastics industry could grow so rapidly was because the equipment needed to form plastics required few new concepts, but instead relied on adaptations of shredders, calendaring machines, two-roll mills, and extruders. Not to diminish the differences, but the new machinery undeniably benefited from its deep roots in the precursor forms that existed even when Alexander Parks, John Wesley Hyatt, and Leo Baekeland first started making their products.

Footnotes:

¹ For a hagiographic biography see Rev. Bradford K. Peirce, Trials of an Inventor: Life and Discoveries of Charles Goodyear (New York: Carlton& Porter, 1866), p. 15 Peirce writes, that his biography, published six years after Goodyear’s death, that he was to “present a fine study, and an admirable example, for young Americans whose minds are quickened by the splendid results which have followed the inventive faculty of our countrymen, and given a bias in that direction to their own thoughts.”

² Michael J. Tarkanian and Dorothy Hosler, “American’s First Polymer Scientists: Rubber Processing, Use and Transport in Mesoamerica,” Latin American Antiquity, Vol. 22, No. 4, (December, 2011), 469-486.

³ Penny Le Couteur and Jay Burreson, Napoleon’s Buttons: 17 Molecules that Changed History (New York: Penguin Group, 2004)

⁴ https://www.imagesdoc.com/blog/questions-nature/comment-certaines-plantes-produisent-elles-du caoutchouc-lou-8-ans

⁵ J. Syme, Esq., “On a Substance from Coal Tar,” Annals of Philosophy, or Annals of Chemistry, Mineralogy, Mechanics, Natural History, Agriculture, and the Arts, Vol. 12, (July-December 1818), 112-113.

⁶ Perhaps to throw off his competitors, Hancock named his shredder a “pickle,” despite it sharing no features with such an item. https://pslc.ws/macrog/exp/rubber/bepisode/pickle/pickle02.htm. A machine known as a “Pug Mill” for kneading clay seems to serve as the antecedent form for the pickle, and the coal-gas industry supplied naphtha, an unappreciated byproduct, which was used as a solvent for the caoutchouc. See, William Woodruff, “Growth of the Rubber Industry of Great Britain and the United States,” The Journal of Economic History, Vol. 15, No. 4 (December 1955), 376-391.

⁷ Nathaniel Hayward, Some Account of Nathaniel Hayward’s Experiments with India Rubber, Which Resulted in Discovering the Invaluable Compound of the Article with Sulphur, (Norwich: Bulletin Job Office, 1865), 6.

⁸ E. M. Chaffee, 1836 Specification of Letters Patent No. 16, dated August 31, 1836. https://patentimages.storage.googleapis.com/83/0a/cd/883996267002eb/US16.pdf

⁹ Cai Guise-Richardson, “Redefining Vulcanization: Charles Goodyear, Patents, and Industrial Control, 1834-1865,” Technology and Culture Vol. 51, No. 2 (April 2010), 357-387.

¹⁰ UNITED STATES PATENT OFFICE. CHARLES GOODYEAR, OF NEW YORK, N.Y. IMPROVEMENT IN INDIA RUBBER FABRICS, Specification forming part of Letters Patent No. 3,633, dated June 15, 1844. Goodyear got into a patent dispute, actually many of them, in 1844 with Thomas Hancock who also patented rubber stabilization on November 28, 1843. See, William Woodruff, “Origins of an Early English Rubber Manufactory,” Bulletin of the Business Historical Society, Vol. 25, No. 1 (March 1951), 31-51.

¹¹ https://glycon.com/history-feedscrew/

¹² https://roylesystems.com/about-royle/history/ Royle was founded in 1855 in Paterson, New Jersey, USA, by John Royle and his two sons, John and Vernon, which was the basis for the original company name, John Royle & Sons. The company thrived on the capabilities of John, the machinist, and Vernon, the engineer. Royle developed the screw type extruding machine, which was patented in 1885. The extruder line of products was first developed for the rubber industry as the automobile industry grew, and then expanded to serve the wire and cable industry as the demand for electricity and telephones grew. Royle still serves the rubber and wire and cable industries with its primary products.

CONTACT US TO LEARN MORE: 704-602-4100